I recently finished How Big Things Get Done (book notes forthcoming). The Empire State Building was a case study in the book, referencing another book, Building the Empire State, a collection of notes from the building’s construction. I bought it, looking for specific tactics on how they ensured quality. I wanted to understand how they did it without the technology and tools we have today, specifically exploring their time management techniques and how they planned the work. (They didn’t have Procore or electronic documents, and yet even with these tools now, teams still feel they don’t have time. I want to dig deeper on why this feeling is so prevalent with such amazing modern tools at our disposal.)

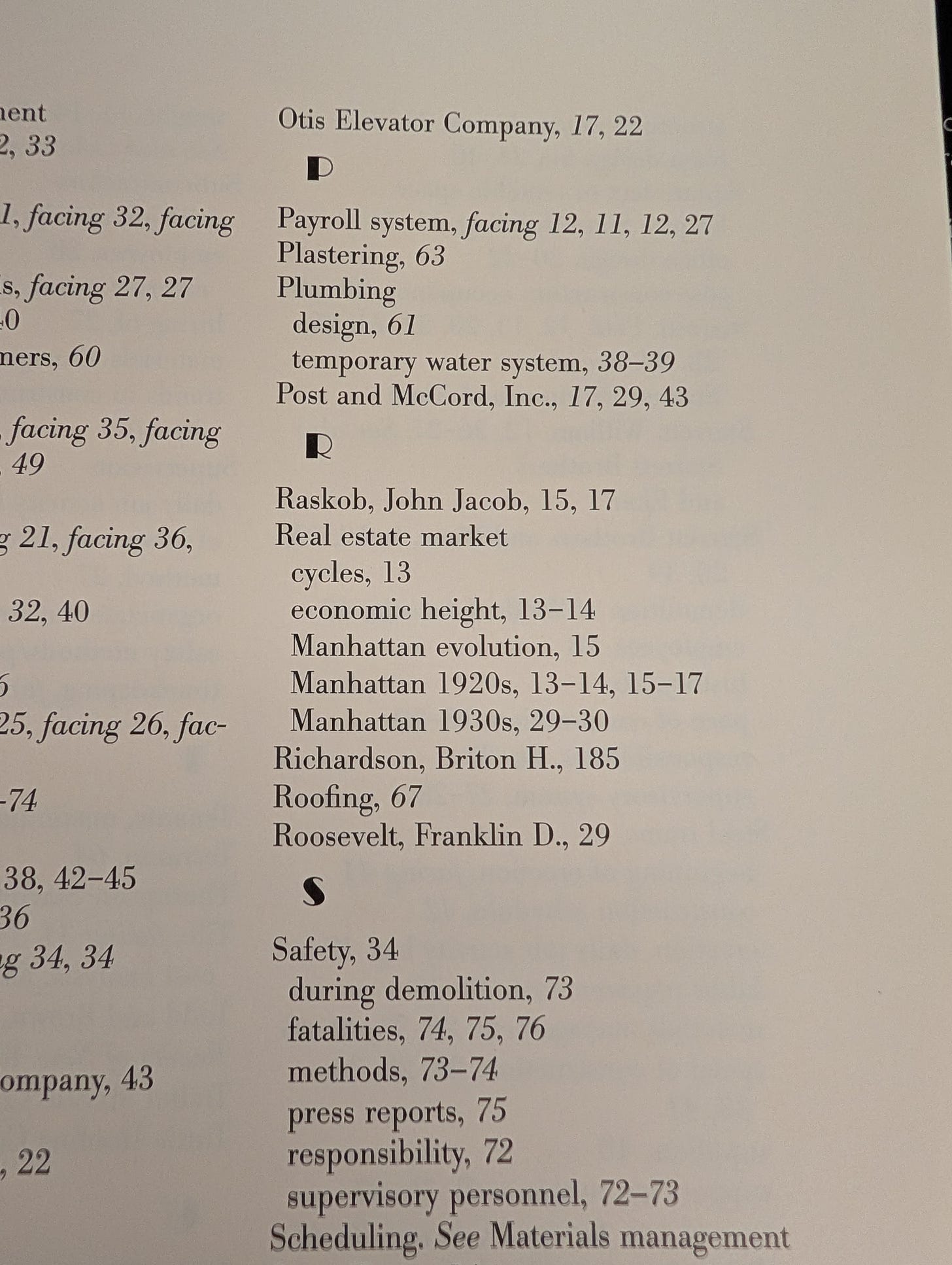

I scanned the book when it arrived, not seeing much specifically about a systematic quality plan or system. Then I got to the index. There’s no “q” section. Nothing mentioned about “quality” (at least on my first quick review – I have yet to read the book cover to cover).

This may be backwards for the industry quality professionals, but I keep thinking: Why do quality programs exist? What’s the real reason? Do we really need the programs because without them, workers will do a poor quality job? Call me naive, but I refuse to believe workers care that little about their work. (Enough of them anyway – there’s a line we cross when enough people may not care that the overall work is in fact impacted negatively, but there should be enough forward-thinking leaders in the industry to prevent a complete meltdown).

More to come as I continue thinking about this.

You can get more quick thoughts and ideas like this from the Deconstrategy Newsletter.

Leave a Reply